ELECTRO-FORMING

Essentially, electroforming is the same process as electroplating. Electricity flows from an anode to the work piece, depositing a layer of metal onto the work piece. The difference is that in electroplating we apply a relatively thin layer of metal as a surface finish. In Electroforming we apply a much thicker layer. This layer can be as thick as 1 or 2 mm and is strong in itself, ie. It no longer requires the original piece (mould or mandrel) for strength.

We can use the electroforming technique for plating onto metallic and non-metallic objects. Non-metallic objects have to be made conductive first by the application of a metallic paint. It doesn’t matter if this non-metallic object doesn’t have much strength in itself (such as a plant leaf). The metal which is electroformed around the object will make it rigid. In this way very unusual and interesting pieces of jewellery can be made. This technique can also be used to metallise resin or wax casts, solid 3D prints and a multitude of other pieces. We electroform in copper and can then plate in the finish of your choice.

Please contact us if you have an electroforming requirement.

A customer brought two pendants to us, with the request to reconstruct the missing bird of one of the pendants. We made a mould from the intact pendant and electroformed the mould in copper. The mould and electroform have copied all the original detailing. Note that when working with moulds, the mould-facing side of the electroform typically becomes the main surface.

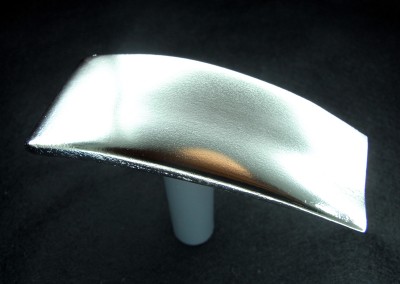

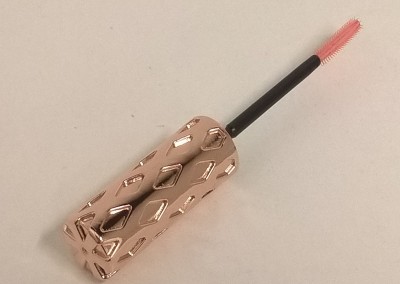

For this particular job, silicone rubber moulds, supplied by our customer, were made conductive and electroformed for 48 hours. During this time a sufficient layer of copper was deposited for the electroforms to be strong and self supporting. The electroformed sections were then sent back to the customer for finishing and assembly.

Silicone Rubber Mould

Unfinished Sections straight after Electroforming